Smart technical documentation in the digital twin

Intelligently connecting product data and product knowledge

We support the integration of your technical documentation into the digital twin of your products to provide context-related, personalized, and up-to-date information.

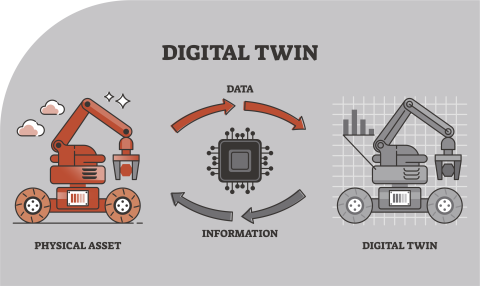

A digital twin is a dynamic, data-driven representation of a physical machine or system. It accompanies the physical product throughout its entire lifecycle, from design and commissioning to maintenance and modernization. In mechanical engineering, digital twins enable predictive maintenance, optimized operations and data-driven services that enhance customer loyalty.

Traditionally, technical documentation, such as manuals, maintenance instructions, and safety information, has been maintained separately from product data management. However, in an increasingly connected industrial environment, this separation is no longer appropriate. Integrating technical documentation into the digital twin creates new opportunities: service and users have direct access to context-specific, personalized information, documents are automatically updated when product changes occur, and legal certainty is increased thanks to consistently traceable content.

A new generation of technical documentation: variant-specific and easy to update

We help you integrate your technical documentation into the digital twin of your products. Together, we will lay the groundwork:

- Modularize and structure technical documentation. For documentation to be integrated into the digital twin, it must be modular and machine-readable. Only then can individual components or functions be linked to the corresponding documentation. We help transform your documents into structured, modular content with the right information architecture and systems.

- Provide variant control down to the configured single product. The documentation must match the specific product configuration. With variant configuration, you can automatically generate configuration-specific documentation.

- Develop a metadata model. We develop semantic metadata models that link documentation modules to components in the digital twin based on established standards, such as iiRDS and AASX.

- Create interfaces between product data and documentation. Efficient integration requires suitable interfaces that enable documentation variants to be controlled automatically via product data and that enable technical data to be imported automatically into the documentation. This creates a company-wide data supply chain that ensures accurate technical data and customized documentation. This is how we work.

Your contacts

for smart documentation with the digital twin

The digital twin as key to smart technical documentation. This is how we work

- Analyze requirements and the current state. We will work with you to determine which product data is available, which product variants are delivered, and how your current documentation processes work. We will also assess the requirements for integrating technical documentation into the digital twin and examine the current state of your digitalization projects.

- Develop an information architecture for modular, variant-ready documentation. We will work with you to develop content structures, variant logic, and a metadata model for your technical documentation. We rely on established standards, such as iiRDS. Knowledge graphs can be used for semantic metadata modeling or product data integration.

- Configure the authoring environment or content management system. We will implement the modular and semantic information architecture within your authoring environment, enabling your technical writers to create variant-specific documentation.

- Set up your content or data supply chain. We create interfaces to systems like PLM, PIM, or ERP to integrate metadata, product configuration, or technical data.

- Implement content delivery. We set up delivery channels for your content in formats such as HTML, iiRDS packages, AASX packages, and JSON for apps.

- Provide training and support. We assist with the rollout, train your technical writers as needed, and help you optimize your processes continuously.

Learn more about the digital twin in our FAQs.

FAQs – Frequently asked questions about the digital twin

What is a digital twin?

A digital twin is a virtual representation of a product that includes all of its properties and variants. It contains design, operational, maintenance, and condition data, which is often provided in real time. The goal is to digitally map and optimize the entire product lifecycle.

What role does the digital twin play in technical documentation?

The digital twin is essential when documentation needs to be automatically generated and tailored to specific product configurations. It provides the necessary information to identify the content relevant to a particular variant. This allows configuration-specific documentation to be efficiently created and delivered as a PDF, an iiRDS package, or digitally via a service portal.

Technical documentation should be integrated into the digital twin because it is a key component of product use. Integration makes the documentation context-aware, always up to date, and directly accessible within the digital model—greatly simplifying service, maintenance, and operation.

What are the benefits of integrating technical documentation into a digital twin?

- Better service. Service technicians access relevant instructions directly via 3D models or intuitive user interfaces – without any disruptions in the media format.

- Reduced downtime: Immediate access to spare part data and repair instructions speeds up maintenance processes.

- Higher customer satisfaction: Operators benefit from intuitive, visual guidance, even on mobile devices or through AR glasses.

- Lower documentation effort: Product changes are automatically and consistently reflected in the documentation.

How can technical documentation be integrated into the digital twin?

1) Prepare your strategy

- Define your objectives. What value should the integration deliver: improved service efficiency, legal compliance, enhanced user experience?

- Identify the stakeholders. Involve all relevant teams: engineering, IT, service, product data management, product management, and technical documentation.

- Prioritize the use cases. Select machines or product lines that are best suited for pilot projects.

2) Establish technical prerequisites

- Evaluate the authoring environment. Make sure it supports modular, structured content and metadata tagging for variant control and delivery. Check for support of standards like iiRDS. Learn more about CCMS for technical documentation

- Develop a metadata model and strategy. Define classifications and semantic tags needed for intelligent content handling. More on metadata models

- Evaluate interfaces and set up the data supply chain. How can CCMS, PLM, ERP, and IoT platforms communicate effectively?

3) Prepare content

- Modularize information. Break content into small, reusable units.

- Add visual elements. Integrate 3D graphics, exploded views, or AR components.

- Enable contextualization. Link content to real-time product data (e.g., "If component X fails, show instruction Y").

4) Implement integration

- Connect content to the digital twin. Use product IDs or metadata to link documentation to the virtual model.

- Create a test environment. Run pilot programs to validate functionality and user experience.

- Collect feedback. Involve service technicians, customers, and sales teams to refine the solution.

5) Roll out and scale

- Train users. Equip technical writers, service staff, and sales teams with the necessary skills and knowledge.

- Set up maintenance workflow.: Define how content updates will be managed and sustained.

- Plan for expansion. Scale the solution to additional product lines, regions, or business units.

What is the Asset Administration Shell (AAS)?

The Asset Administration Shell (AAS) is a core concept of the digital twin in Industry 4.0 – and it's becoming increasingly relevant for technical documentation, especially when it comes to standardized, digital delivery of information.

The AAS acts as the digital representation – or "digital envelope" – of a physical product or system. It organizes all relevant information and functions into modular submodels. These submodels can contain technical data, software details, or information of use, such as documentation.

Submodels relevant for technical documentation include:

- Handover documentation – used for the standardized digital transfer of manufacturer documentation to operators or other stakeholders of an asset. It is based on VDI 2770, part 1, and enables structured, machine-readable classification and management of technical documents.

- Intelligent information for use – this submodel is based on iiRDS and aims to provide technical information in a user-friendly, modular, and context-sensitive way. It enhances the "Handover documentation" submodel with semantic depth and dynamic information structures.

- Digital nameplate – contains structured information typically found on the physical nameplate of an industrial device.

With these, technical documentation becomes an integral part of the AAS: machine-readable, standardized, and interoperable – ready for use in service portals, mobile devices, or smart assistance systems.