The challenges of digitalization in technical communication

Corresponding service: Digital transformation consulting

Digital transformation is not limited to changing production processes and automating workflows. It affects many areas of society.

Effects of digitalization

With digitalization, products, business models, value chains, customer behavior and the world of work are changing. This also radically changes the work of technical communicators.

This article was published in: European Association for Technical Communication - tekom Europe e.V. Year Book 2018 (Eds), Annual Book Series, Vol 2, p. 49-62.

Products and machines

Thanks to digitally controlled production, products are manufactured in many variants, right up to individual production. In addition, products are becoming increasingly smarter and more networked: in addition to mechanical and electrical components, they have communication and software equipment for digital tasks:

- Communication between workpieces and products along the value chain, e.g., with manufacturing and logistics systems

- Collection of data on the use and configuration of the product. The manufacturer can aggregate and evaluate this data and thus optimize the use and service life of products and achieve additional service benefits. A typical example is preventive maintenance.

- Communication between products, e.g., for controlling production processes (machine-to-machine communication)

- Communication with the user to optimize usage, individual configuration of product features or networking of systems. Typical applications are smart home systems.

Machines and systems receive what is called a digital twin, which contains all information on variant, configuration, sensor values, maintenance, etc. The twin also includes digital usage information such as operating and maintenance instructions or data sheets.

The manufacture of smart and networked products requires a different product design: the products are given a software layer, a communication layer and matching hardware. On the manufacturer side, cloud solutions are required for the storage, aggregation and evaluation of sensor and measurement data. Product development and design therefore require new competencies such as software development, cloud computing, data analysis, communication technology and usability engineering. The development teams are becoming more interdisciplinary so that these competences can be incorporated (Porter/Heppelmann 2015).

Effects on technical communication

Smart products require smart documentation in the form of intelligent information. Instead of traditional manuals, digital usage information (Fritz 2017) is provided for users and digital twins.

The new application scenarios, such as product individualization and preventive maintenance, require new, standardized types of information and modularized texts that users or applications can retrieve or receive on demand and that support the relevant scenario. Examples include tutorials for setting up a smart home or maintenance instructions that are sent to the service technician based on a measured operating condition.

Therefore, we should develop solution-oriented and task-based technical documentation for different target groups. In addition to the standardization of information types, e.g., guidance and problem-solving, this also requires technical writers to deal more intensively with their target groups and to use usability methods such as personas and customer journeys. Feedback from the field, e.g., from service technicians, must flow back into the documentation more quickly. Faster change cycles and continuous updating and delivery of digital usage information are the logical consequence.

Even if smart products are easier to use, this does not mean the end of documentation, because technical systems become more complex as a result of digitalization. Apart from the legal requirements, documentation is still needed – perhaps not for the standard use cases,but for understanding complex architectures and data flows, and for troubleshooting. It is therefore possible that the documentation contains fewer instructions, but more concepts, troubleshooting assistance, and background knowledge (Becker 2018).

Despite the increasing number of variants, users are less willing to search the documentation for suitable information on the current product and configuration variant. When the usage information is delivered to a machine or system, the variant must be marked explicitly and in a machine-readable way so that the correct information for the variant can be retrieved later on.

Due to the new usage scenarios and the higher number of variants, the amount of documentation required is likely to increase. What is decreasing is the size of the information modules – these are becoming much more fine- grained so that they can be reused for different variants and purposes. At the same time, each module must have a distinct information type and be enriched with metadata so that the intended use and the product variant can be determined automatically.

Business models and value chains

Digitalization affects the entire value chain and the cooperation of all actors along this chain. A possible value chain can look like this:

- Customer requirements and desired product configurations are received and processed digitally.

- Design and manufacturing simulations enable manufacturers to evaluate whether custom production or new product configurations are feasible and what the costs are.

- Manufacturers digitally communicate required delivery quantities and dates with suppliers and transport service providers.

- Production lines are configurable, up to batch size 1. Production planning is done digitally.

- Orders are processed electronically. Customer and supplier profiles enable tailor-made offers.

- Deliveries are monitored so that delivery dates are calculated and deliveries can be tracked.

- The product is monitored at the customer site and, if necessary, maintained preventively.

Value chains are thus becoming increasingly agile and flexible, and throughput times are reduced. Innovation cycles are getting shorter.

Digitalization is causing massive and disruptive changes in the market. New products and services emerge, standard products and manufacturers suddenly disappear. New offers are developing that are not based on classic products, but on the provision of platforms (Airbnb), availability (DriveNow, Call a Bike) or services (email services, travel exchanges). Suppliers often combine their products with services in order to offer customers additional benefits (Kaufmann 2015). Examples include energy consulting for homeowners based on data from the SmartHome system and preventive maintenance contracts.

For these new business models, billing models other than the classic unit or hourly price apply. Payment is made per usage quantity or duration, per saving or optimization, for above-average wear and tear or for additional services.

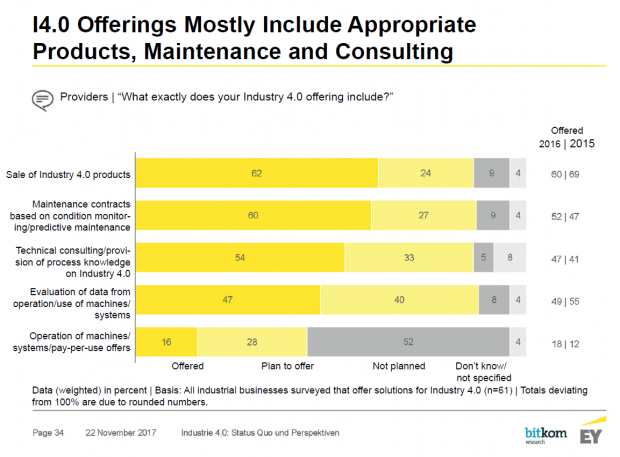

In a study commissioned by Bitkom, industrial companies were asked what their Industry 4.0 offering included (Ernst & Young 2017). In addition to the Industry 4.0 products themselves, maintenance contracts and technical advice are also at the forefront (see Fig. 3).

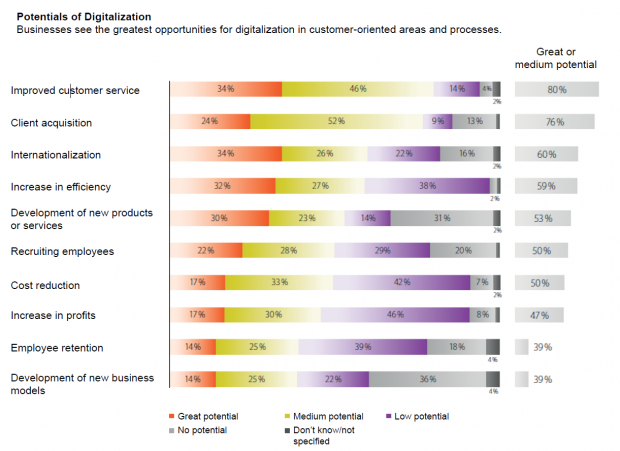

Companies see great opportunities in the new digital business models, as another study shows, especially through improved service (Tata 2017) (see Fig. 4).

Effects on technical documentation

Documentation also becomes part of the digital value chain. If technical communicators want to to keep pace with digitalized processes, they cannot keep working the way they are used to, with large PDF documents and rigid document-based update and approval processes.

For example, a customer-specific configuration or production of products requires a flexible, feature-driven information architecture that supports technical communicators in quickly assembling a suitable documentation for a new product variant. The higher the number of variants, the less time is available for manual adjustments and editing of documents.

In this context, it is very important that different departments cooperate in the classification of characteristics for products and documentation. Product features and variant features for documentation overlap to a large extent, because new product variants require suitable documentation. It is also important for the user experience of the customers that marketing materials, documentation and product texts speak the same language. A common classification or product ontology thus represents a good basis for the digital value chain.

The business models for the products determine how they are used. This must also be reflected in the documentation. If, for example, compressed air is charged per liter consumed in a filling system, the user wants to know where s/he can find the consumption meter and how to reduce consumption.

With the increasing share of services, service documentation is also becoming increasingly important. This may require other types of information than product documentation, such as service reports, error analyses, or video tutorials. Augmented reality applications are also gaining importance. Metadata of the documentation facilitates targeted retrieval of information in service scenarios or augmented reality applications. This includes, for example, metadata for components, product life cycle phases, error states and more.

Digital business models need explanatory information. This opens up a new field of activity for technical communicators. A service must be explained in the same way as a product. For a service-oriented business model, it is important that marketing, documentation, and service departments work well together, use the same terminology, and reuse content for different purposes across departments.

The shortened innovation cycles mean that product and service information must be made available in a short time. Here, too, a modular and standardized information model as well as automated publication and delivery are useful in order to be able to react quickly to requirements.

Customer behavior and expectations

With digitalization, user behavior changes as well. This not only applies to technical documentation, but also to software programs, apps, books, newspapers, etc. Everything must be readable and operable on small screens. We expect that information can be retrieved or at least synchronized via the Internet. Readers do not want to know the source of a particular piece of information, but expect the information from different sources such as marketing, production and documentation to be consistent.

Irrespective of our age, we are now used to consuming information in small pieces and using filters to reduce long search result lists to the piece of information really needed. In this context, new search and navigation standards have developed for websites that users instinctively apply to documentation portals. Users are also used to a portal that knows them and individualizes the selection of information.

Visual support for learning and knowledge processes is becoming more and more a matter of course, not least due to the higher bandwidth of communication lines. Videos are embedded in many websites and augmented reality is becoming more common.

And it’s not just the machines that network, we’re also becoming more and more digitally networked - via communities, social networks, company networks, learning platforms. We receive newsletters, blog feeds and other notifications.

Effects on technical documentation

Technical documentation becomes digital usage information that users can read and search on mobile devices, on the screen at the machine or on the company PC. The properties described above are also important here: modular, metadata-enriched and machine-readable information modules with standardized types of information that can be used for various purposes.

Working environment and corporate culture

With digitalization, our world becomes more complex and faster. Many things change in a short time. This is why we speak of a VUCA world:

- V = volatile, i.e. rapidly changing

- U = uncertain

- C = complex

- A = ambiguous

Rigidly organized, non-agile companies have difficulty responding to disruptive market changes. Companies must quickly respond to new digital trends or define them; otherwise, they will lose touch. Examples such as Nokia in the mobile phone sector, or Kodak in photography, which were pushed out of the market by disruptive changes, have proven this.

Hierarchical and rigid forms of organization often lead to long decision-making paths. Decisions are made by management, i.e. by people who have the authority but not necessarily the knowledge to make these decisions.

At the same time, companies are struggling with an increasing shortage of skilled workers. Companies must therefore pay more attention to the needs of their employees. Today, factors like the working atmosphere, meaningful work and the compatibility of family and career play a greater role than a high salary.

In this context, new organizational forms for companies are developing, e.g., sociocratic instead of hierarchical structures or agile organizations. These are characterized by self-determined work, open communication (also concerning errors), quick decisions and a stronger orientation towards the customer (Laloux 2015 and Schüttelkopf 2015). This helps companies to master the challenges of the VUCA world.

Digitalization creates many new opportunities for cooperation. We can form teams and work in projects across locations because cloud and web solutions let us work everywhere. Video conferencing, intranets and chats allow us to communicate with colleagues anywhere in the world.

For the new smart products we need interdisciplinary teams with different competences in design, software development, usability, documentation, service and marketing. This blurs the traditional boundaries between departments and questions existing processes.

But the new way of working also requires that we continue learning for the rest of our life. Nothing stays the same. New programs are constantly added, the cloud solution is updated overnight and colleagues suddenly work in a new time zone. Companies must therefore establish change management processes and training programs to prevent resistances to changes.

Implications for Technical Communicators

The changes in the world of work also affect technical communicators, because they need new skills to integrate into digital business processes and business models (see also Becker 2018).

High IT competence for the use of new business technology, documentation technology and means of communication

Strategic thinking for the integration of the content strategy into the company‘s digitalization strategy

- Agile project management and business thinking for the implementation of digitalization projects

- Knowledge required for the documentation of smart products with intelligent information: software documentation, modularization, content management, and metadata management

- User orientation, knowledge of usability engineering

- Networked working

- International technical communication for globalized companies

- Knowledge management

The good news is that technical communicators are well prepared for the digital transformation. Developing user-oriented technical documentation has always required editors to work and communicate across departments, to understand complex technical contexts and processes, and to write good texts. And most of us have to deal with many different IT systems on a daily basis. As our profession and the products we document are constantly evolving, we are used to lifelong learning.

Company-wide digitalization strategy

In summary, it can be said that digital transformation can only succeed if there is a company-wide digitalization strategy that is not driven solely by IT, but anchored in all areas of the organization and controlled by a central board. Technical communicators can make a valuable contribution here and should embed digitalization projects for technical documentation into the overall strategy of the organization.

Digital transformation of documentation

Digital transformation is not an automatic process, but costs companies a lot of energy and effort for a benefit that cannot always be clearly quantified. Technical documentation is also part of this area of conflict.

Obstacles for companies

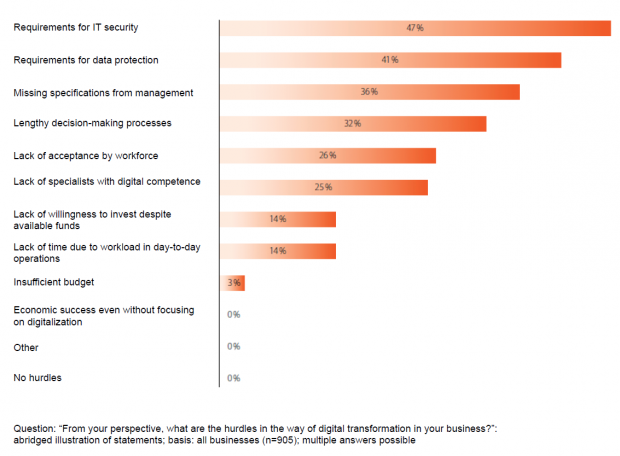

In a survey commissioned by Bitkom Research, the following obstacles to digital transformation were identified (Tata 2017). In the top places are the requirements for IT security and data protection as well as missing specifications from management (see Fig. 7).

Common causes for the failure of digitalization projects include (Bitkom 2018):

Inadequate integration into the company’s digitalization strategy or lack of an overall strategy for the company’s digital transformation

- Insufficient budget

- Inadequate or non-existent change management

- Lengthy decision-making processes

- Rigid organizational structures

- Missing standards

These obstacles must also be taken into account for digitalization projects in technical documentation.

The importance of standards

Standards are an essential prerequisite for a successful digital transformation, because the networking of products and their usage information crosses company boundaries. Uniform interfaces for exchanging data and requesting services and information are required.

In the area of industry, there are already several standardization projects, especially in connection with Industry 4.0 (Nuding 2017). Here are just a few examples:

- RAMI 4.0

- OPC-UA

- Automation ML

- VDI Guideline 2770, “Digital Manufacturer Information”

- Digital CV file, e.g. DIN-SPEC 91303

- iiRDS

For technical editors, the iiRDS and VDI 2770 standards are important in connection with intelligent information.

The transformation of technical documentation

Transforming documentation into intelligent information is one of the most important tasks for the documentation departments of many companies.

Intelligent information is modular, format-neutral and can be accessed via metadata and full-text search. Metadata enables applications to intelligently retrieve technical documentation and deliver exactly the piece of information that fits the application context and role of the user (Parson 2017).

A transformation of classical document-oriented documentation and processes requires far-reaching changes in the field of technical communication:

- Modularization of content

- Alignment of content with new, digital processes and business models: target group-oriented, variant-oriented, task-based and solution-oriented

- Standardization of information types, also across departments

- Linking documentation content with other types of information from service, marketing and training

- Development of a metadata model that supports reuse and variant management on the author side and context-dependent use on the application side. The basis for this should be a common taxonomy/ontology shared by several groups within the organization.

- Use of format-neutral and standardized file formats for content and metadata; separation of content and metadata

- Development of a flexible and scalable information architecture that enables the dynamic composition of information products on the basis of feature classification

- Automated publication of information products and continuous delivery in a standardized format

- Embedding of visual information (image, video), e-learning and augmented reality (if applicable)

- Embedding of real-time data and sensor data

- Integration of user feedback

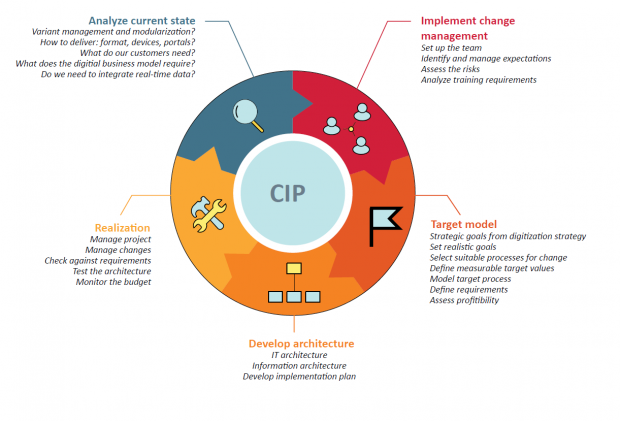

Process model

A structured approach helps technical communicators transform their documentation into intelligent information. The transformation should take place in a process of continuous improvement (CIP), so that the communicators can adapt flexibly to changing requirements:

In order to avoid failure on the road to intelligent information, the following recommendations apply:

- Proceed iteratively, i.e. in manageable sub-phases with limited and measurable goals.

- Use an agile project management methodology such as Scrum to help you set sub-phase goals and review results.

- Form an interdisciplinary team in which different competences are combined: e.g. technical communication, IT, company organization and product management.

- Set up change management right at the beginning of the project to avoid resistance to changing work processes.

- Think across departments.

- Take regulatory requirements into account to ensure that the documentation continues to comply with standards.

- If possible, rely on standards for the information and IT architecture. They guarantee sustainable solutions.

Bibliography

- Bitkom (2018): Herausforderungen bei der Digitalisierung von Geschäftsprozessen meistern. www.bitkom.org [27.08.2018].

- Fritz, Michael (2017): Was ist Intelligente Information? In: Hennig, Jörg/Tjarks- Sobhani, Marita (Hrsg.): Intelligente Information. Stuttgart: tcworld GmbH (tekom Schriften zur Technischen Kommunikation 22) 11-25.

- Becker, Birgit (2018): Information 4.0 – Anforderungen an Technische Redakteure. Masterthesis, Donau-Universität Krems, Department für Wissens- und Kommunikationsmanagement.

- Ernst & Young GmbH (2017): Industrie 4.0: Status Quo und Perspektiven. Studie durchgeführt von Bitkom Research. https://www.bitkom-research.de/Industrie- 40-Status-Quo-und-Perspektiven-2017 [13.09.2022]. The study is no longer available online.

- Kaufmann, Timothy (2015): Geschäftsmodelle in Industrie 4.0 und dem Internet der Dinge (essentials). Wiesbaden: Springer Vieweg.

- Nuding, Win (2017): Standards im Umfeld von Industrie 4.0. In: Hennig, Jörg/ Tjarks-Sobhani, Marita (Hrsg.): Intelligente Information. Stuttgart: tcworld GmbH (= tekom Schriften zur Technischen Kommunikation 22) 67-80.

- Laloux, Frederic/Kauschke, Mike (2015): Reinventing Organizations: Ein Leitfaden zur Gestaltung sinnstiftender Formen der Zusammenarbeit. http://www.reinventingorganizations.com/ [27.08.2018].

- Parson, Ulrike: Das Datenmodell der Technischen Dokumentation in iiRDS. In: Hennig, Jörg/Tjarks-Sobhani, Marita (Hrsg.): Intelligente Information. Stuttgart: tcworld GmbH (= tekom Schriften zur Technischen Kommunikation 22) 26-39.

- Porter Michael E./Heppelmann, James E. (2015): How Smart, Connected Products Are Transforming Companies. https://hbr.org/2015/10/how-smart-connected- products-are-transforming-companies [13.09.2022].

- Schüttelkopf, Elke M. (2015): Lernen aus Fehlern. Wie man aus Schaden klug wird. Freiburg: Haufe Verlag.

- Tata Consultancy Services (2017): Digitalisierung. Deutschland endlich auf dem Sprung? Trendstudie von Tata Consultancy Services (TCS) und Bitkom Research https://studie-digitalisierung.de/ [27.08.2018].